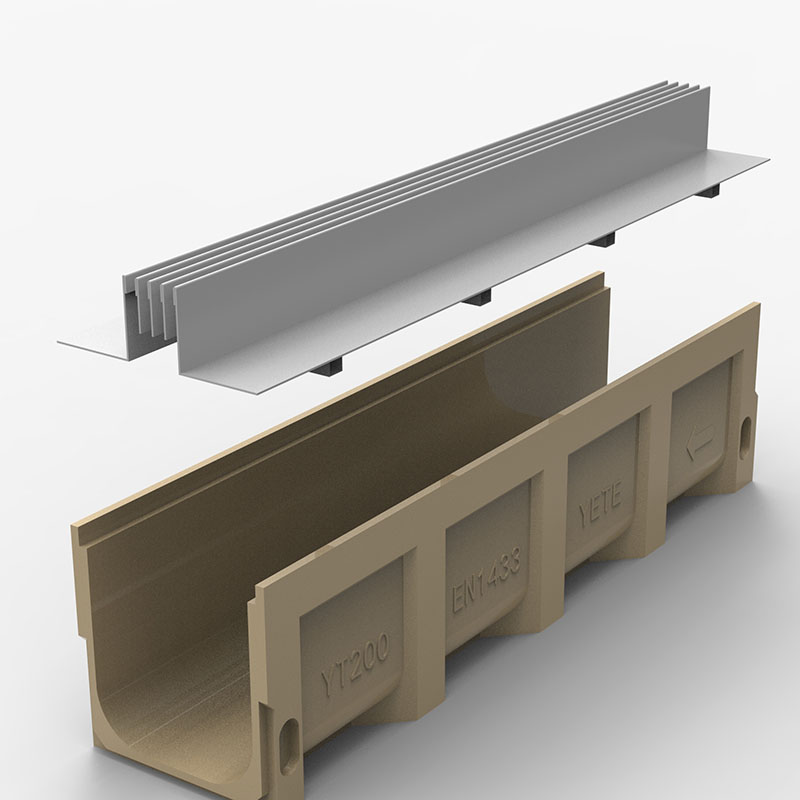

High Load Capacity Polymer Concrete Monolithic Drainage Channel Drainage System

Product Description

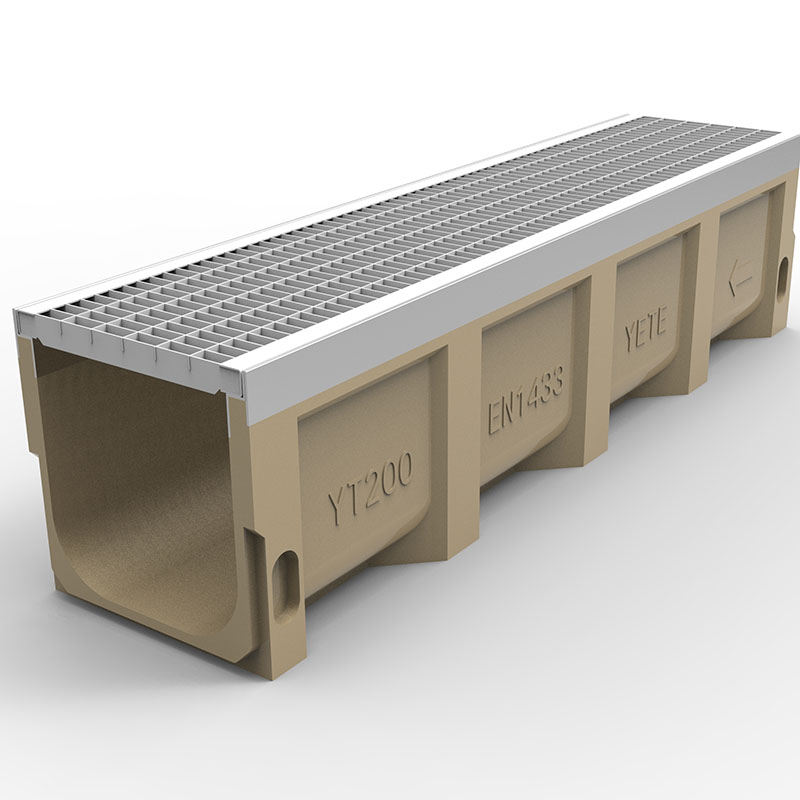

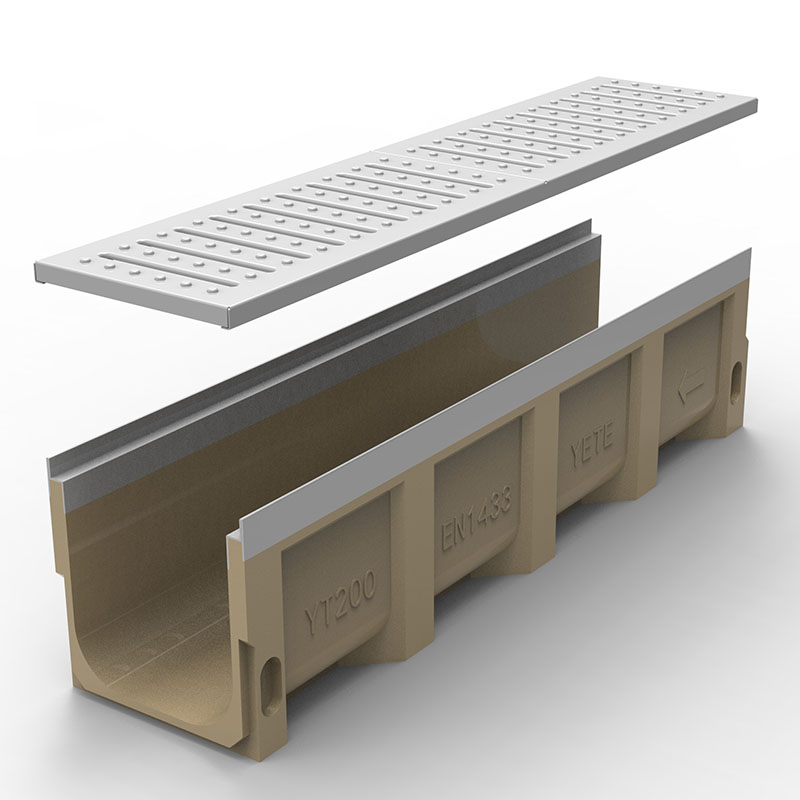

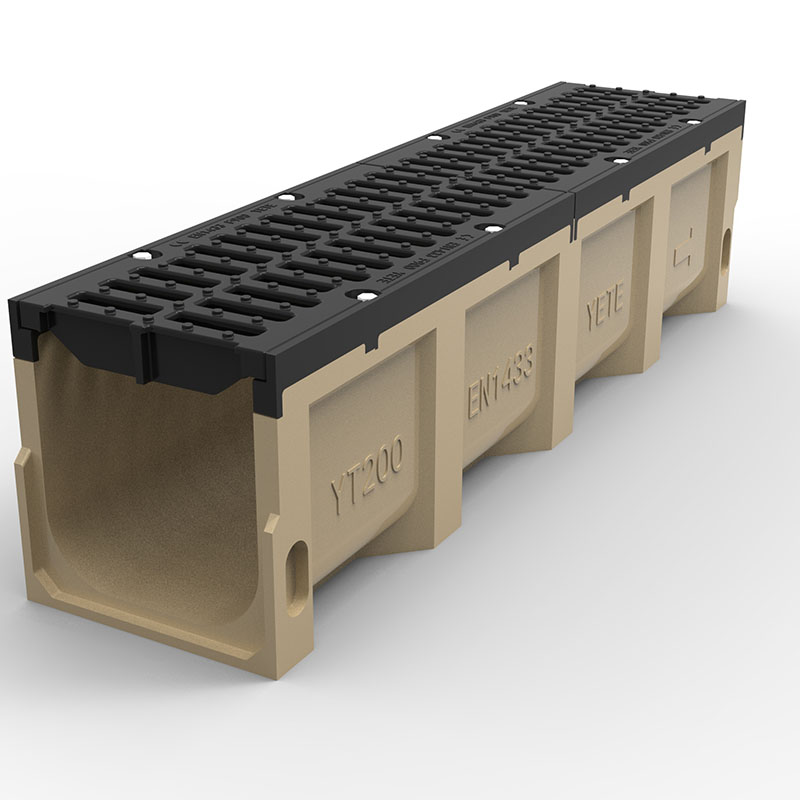

Monolithic drainage channel is a drainage channel system in which both the channel and cover are made in one piece. Monolithic drainage channel is made uniform in polymer concrete. This raw material represents the highest load capacity and long-life maintenance-bility. To this is added the low weight, whereby monolithic drainage channel can be easily and readily installed.

Product Characteristics

The monolithic drainage channel possesses several distinctive features:

1. Seamless Construction: The monolithic drainage channel is designed and constructed as a single, continuous unit, without any joints or seams. This seamless construction ensures a smooth and uninterrupted flow of water, minimizing the risk of clogs or blockages.

2. High Strength and Durability: The monolithic channel is built using durable materials such as reinforced concrete or polymer concrete, providing excellent strength and long-term durability. It can withstand heavy loads and resist damage from traffic, making it suitable for high-traffic areas.

3. Customizable Design: The monolithic channel can be customized to meet specific project requirements. It can be designed with various widths, depths, and slopes to effectively handle different water flow rates and drainage needs.

4. Efficient Water Flow: The seamless construction of the monolithic channel promotes efficient water flow, ensuring rapid and effective drainage. It helps prevent water accumulation, reduces the risk of flooding, and maintains the integrity of surrounding structures.

5. Chemical and Corrosion Resistance: Depending on the material used, the monolithic channel can offer excellent resistance to chemicals, including acids and alkalis. This resistance makes it suitable for applications in industrial environments or areas with potential exposure to corrosive substances.

6. Easy Installation and Maintenance: The seamless design of the monolithic channel simplifies installation, as there are no joints or connections to worry about. It also facilitates easier maintenance, with fewer areas prone to debris buildup or potential damage.

7. Versatile Applications: The monolithic drainage channel is suitable for a wide range of applications, including roadways, parking lots, industrial areas, commercial spaces, and residential areas. It can effectively manage water runoff in various settings.

8. Enhanced Safety: The seamless construction minimizes tripping hazards and improves overall safety. It provides a smooth surface for pedestrians, cyclists, and vehicles, reducing the risk of accidents or injuries.

9. Longevity and Cost-effectiveness: The monolithic channel's durable construction and resistance to wear and tear contribute to its longevity, resulting in reduced maintenance and replacement costs over time.

In summary, the monolithic drainage channel offers a seamless, strong, and efficient solution for effective water drainage. Its seamless construction, high durability, customizable design, and versatile applications make it an ideal choice for various environments, ensuring efficient water management and long-term cost-effectiveness.

Product Applications

The monolithic polymer concrete drainage channel serves a wide range of purposes due to its versatility. Here are some key applications:

1. Road Infrastructure: These channels are essential components of road and highway drainage systems, efficiently managing surface water runoff to ensure safe driving conditions and prevent road damage.

2. Urban Drainage Systems: They play a crucial role in urban areas by effectively collecting and directing stormwater runoff, reducing the risk of flooding and water accumulation in streets, sidewalks, and public spaces.

3. Commercial and Retail Spaces: Monolithic polymer concrete drainage channels are commonly used in shopping centers, commercial complexes, and parking lots to control water drainage, ensuring safe pedestrian access and protecting structures from water damage.

4. Industrial Facilities: Monolithic polymer concrete drainage channels are widely used in industrial environments to efficiently drain wastewater, manage liquids, and maintain a clean and safe working environment.

5. Residential Areas: These channels find applications in residential settings, including driveways, gardens, and patios, effectively managing water runoff and preventing waterlogging or property damage.

6. Landscaping and Outdoor Areas: They are commonly employed in landscaping projects, parks, and gardens to control water drainage, preventing water accumulation and ensuring the health of plants and soil stability.

7. Sports Facilities: These channels are installed in sports fields, stadiums, and recreational areas to efficiently drain rainwater, providing optimal playing conditions and reducing the risk of injuries.

8. Airports and Transportation Hubs: Monolithic polymer concrete drainage channels are essential for managing water runoff on airport runways, taxiways, and other transportation areas, ensuring safe operations and reducing hazards.

9. Food Processing and Industrial Kitchens: They are suitable for areas requiring regular cleaning, such as food processing facilities and industrial kitchens, effectively draining liquids and maintaining hygiene standards.

In summary, the monolithic polymer concrete drainage channel finds extensive usage in road infrastructure, urban areas, commercial spaces, residential areas, industrial facilities, landscaping projects, sports facilities, airports, and food processing areas. Its seamless construction, high durability, and efficient water management capabilities make it an essential component for ensuring safety, functionality, and effective water drainage in various environments.

Load Class

A15: Areas which can only be used by pedestrian and pedal cyclist

B125: Footways, pedestrian areas, comparable areas, private car paks or car parking decks

C250: Curb sides and non-trafficked areas of hanrd shoulders and similar

D400: Cariageways of roads (including pedestrain streets), hard shoulders and parking areas, for all types of road vehicles

E600: Areas subjected to high wheel loads, e.g. ports and dock sides, such as forklift trucks

F900: Areas subjected to specially high wheel load e.g. aircraft pavement

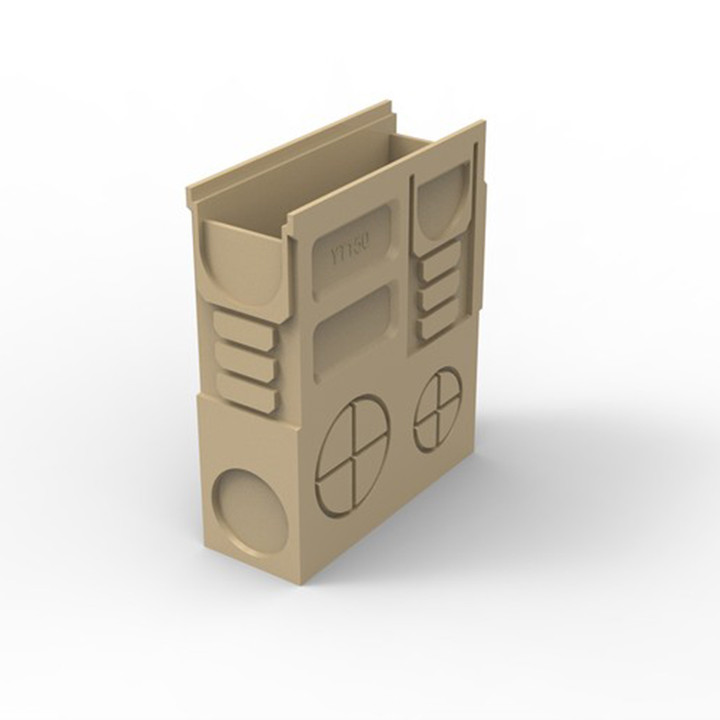

Different Options

Certificates

Office and Factory