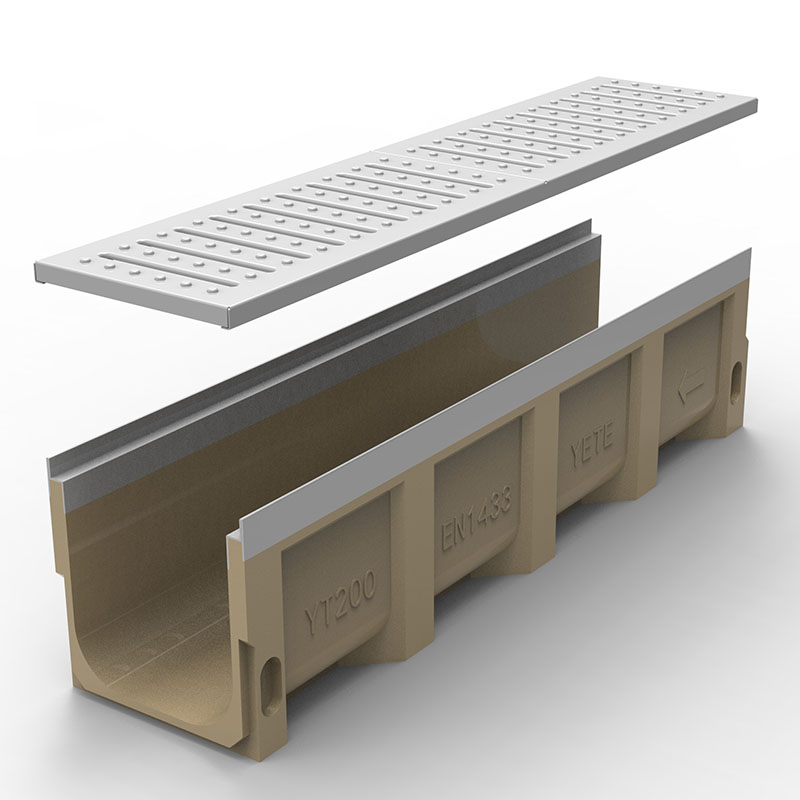

Drainage Channel With Stamped Cover

Product Description

Polymer concrete channel is a durable channel with high strength and chemical resistance. It is long lasting and has no hazard to environment. With Stainless Steel cover, it can widely used for drainage systems for residenstial, comercial and industrial use.

Product Characteristics

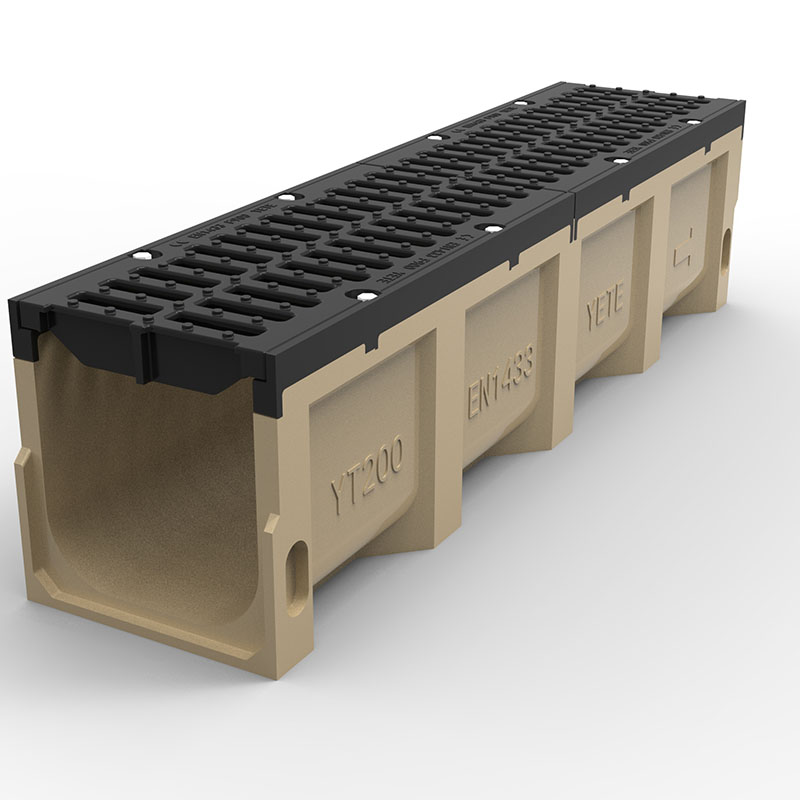

The polymer concrete drainage channel with a stamped cover possesses several distinctive features:

1. High Strength and Durability: The polymer concrete material used in the channel construction provides exceptional strength and durability, ensuring long-lasting performance even in demanding environments.

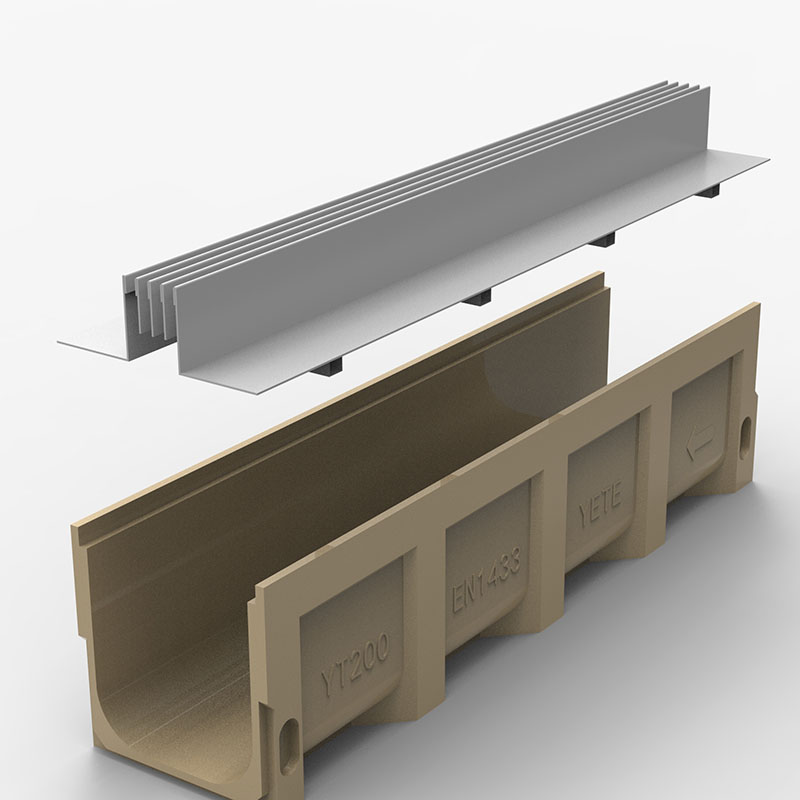

2. Stamped Cover Design: The channel is equipped with a stamped cover that adds an attractive and decorative element to the installation. The stamped pattern can mimic various textures, such as brick, stone, or tile, enhancing the aesthetic appeal of the drainage system.

3. Efficient Water Drainage: The channel is designed with a stamped cover that allows for efficient water flow, preventing water accumulation and minimizing the risk of surface damage or flooding.

4. Chemical Resistance: Polymer concrete is highly resistant to chemicals, acids, and alkalis, making it suitable for applications where exposure to corrosive substances is a concern.

5. Lightweight Design: The polymer concrete construction makes the channel lightweight, facilitating easier handling, installation, and maintenance.

6. Customizable Options: The polymer concrete drainage channel with a stamped cover is available in various sizes, shapes, and load ratings, offering flexibility to meet specific project requirements.

7. Anti-Clogging Design: The stamped cover design includes openings that prevent debris, leaves, and other objects from entering the channel, ensuring uninterrupted water flow and reducing the need for frequent maintenance.

8. Easy Installation and Maintenance: The lightweight nature of the channel and the stamped cover simplifies installation and maintenance tasks, saving time and effort.

9. Versatile Applications: The product is suitable for a wide range of applications, including road infrastructure, urban drainage systems, commercial complexes, residential areas, and industrial facilities.

In summary, the polymer concrete drainage channel with a stamped cover offers a durable, aesthetically pleasing, and efficient solution for effective water drainage. Its high strength, chemical resistance, stamped cover design, and customizable options make it a versatile choice for various applications, ensuring reliable performance and enhancing the visual appeal of the surrounding environment.

分享

Product Applications

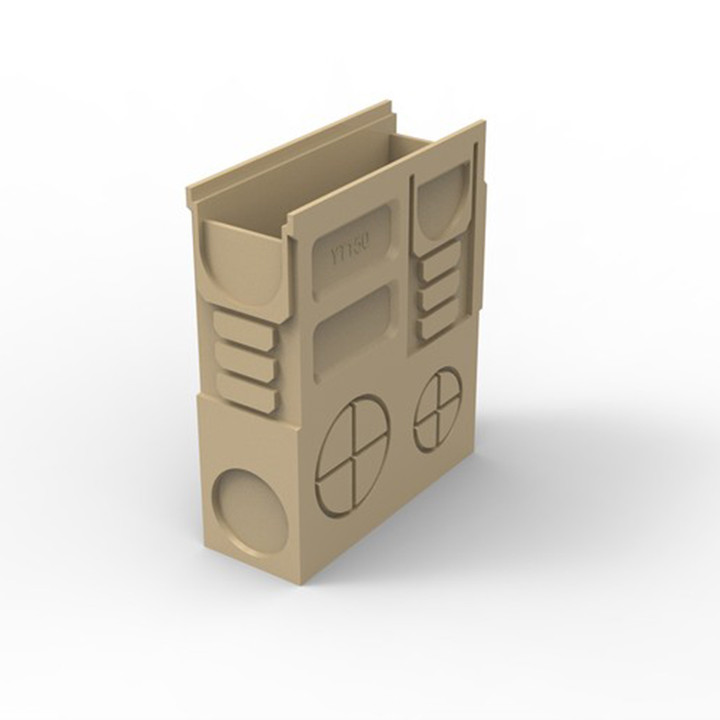

The polymer concrete drainage channel with a stamped cover serves various purposes due to its versatility. Here are some key applications:

1. Road Infrastructure: These channels are crucial components of road and highway drainage systems, efficiently managing surface water runoff to ensure safe driving conditions and prevent road damage.

2. Urban Drainage Systems: They play a vital role in urban areas by effectively collecting and directing stormwater runoff, reducing the risk of flooding and water accumulation in streets, sidewalks, and public spaces.

3. Commercial and Retail Spaces: Polymer concrete drainage channels with stamped covers are commonly used in shopping centers, commercial complexes, and parking lots to control water drainage, ensuring safe pedestrian access and protecting structures from water damage. The stamped cover adds an aesthetic touch to the overall design.

4. Residential Areas: These channels find applications in residential settings, including driveways, gardens, and patios, effectively managing water runoff and preventing waterlogging or property damage. The stamped cover adds visual appeal to the outdoor spaces.

5. Industrial Facilities: Polymer concrete drainage channels with stamped covers are widely used in industrial environments to efficiently drain wastewater, manage liquids, and maintain a clean and safe working environment. The stamped cover adds an element of style to industrial surroundings.

6. Landscaping and Outdoor Areas: They are commonly employed in landscaping projects, parks, and gardens to control water drainage, preventing water accumulation and ensuring the health of plants and soil stability. The stamped cover can complement the desired aesthetic theme.

7. Sports Facilities: These channels are installed in sports fields, stadiums, and recreational areas to efficiently drain rainwater, providing optimal playing conditions and reducing the risk of injuries. The stamped cover can enhance the visual appeal of the sports facilities.

8. Airports and Transportation Hubs: Polymer concrete drainage channels are essential for managing water runoff on airport runways, taxiways, and other transportation areas, ensuring safe operations and reducing hazards. The stamped cover can contribute to the overall aesthetics of the airport or transportation hub.

9. Industrial Kitchens and Food Processing: They are suitable for areas requiring regular cleaning, such as industrial kitchens and food processing facilities, effectively draining liquids and maintaining hygiene standards. The stamped cover can add a decorative touch to the functional space.

In summary, the polymer concrete drainage channel with a stamped cover finds extensive usage in road infrastructure, urban areas, commercial spaces, residential areas, industrial facilities, landscaping projects, sports facilities, airports, and food processing areas. Its efficient water management capabilities, combined with the aesthetic appeal of the stamped cover, make it an essential component for ensuring safety, functionality, and visual enhancement in various environments.

Load Class

A15: Areas which can only be used by pedestrian and pedal cyclist

B125: Footways, pedestrian areas, comparable areas, private car paks or car parking decks

C250: Curb sides and non-trafficked areas of hanrd shoulders and similar

D400: Cariageways of roads (including pedestrain streets), hard shoulders and parking areas, for all types of road vehicles

E600: Areas subjected to high wheel loads, e.g. ports and dock sides, such as forklift trucks

F900: Areas subjected to specially high wheel load e.g. aircraft pavement

Different Options

Certificates

Office and Factory